導航連結

ONE Is A Global Refrigerated Carrier

ONE emerged from the legacy of three leading Japanese liner companies, namely MOL, NYK and 'K' Line. These companies pride themselves on their service-oriented culture which is now embedded in ONE’s DNA. The integration allowed ONE to inherit the three liners’ strong market presence in major reefer markets such as North and South Americas, South Africa, Europe, the Mediterranean, Intra-Asia and Oceania.

ONE is thriving on the combined experience of legacy Japanese shipping companies, with a strong focus on schedule integrity and on time performance which are critical for the transportation of refrigerated cargo segment. Being the third largest, young and state of the art reefer fleet in the world, ONE provides the best in class reliable “cargo care” with optimized services to meet our customers’ diversified needs.

Whether avocados and bananas from South America, chilled/frozen meat from North America/Oceania, citrus/grapes from South Africa, dairy/wine from Europe or fresh fruits/vegetables in Intra Asia trade - whatever your product is or wherever your market is around the world, ONE has the unmatched legacy experience and technical expertise, to bring your valued cargo to the market in perfect, freshest condition.

Your Advantages with ONE in Reefer

In ONE we combine best practices of three legacy Japanese companies in reefer trade and our culture is based on Japanese Philosophy of “Kaizen”, which is about continuous improvement in every segment of our business. As a leading carrier in refrigerated cargo segment, it’s our continuous endeavour to provide innovative and cutting-edge solutions for the perishable cargo industry. Our goal is to provide customers with the highest service quality and utmost care to preserve freshness of perishable cargo which we carry in our reefer containers.

- Large and Advanced Reefer Fleet

-

- 3rd largest reefer fleet* in the world equipped with the most advanced technologies

- One of the youngest fleet (average age less than 5 years) with over 250,000 TEU; with good mix of 20ft and 40 HC Reefer containers

- Good diversity of container type and machinery to meet customers growing demand.

- All Reefer containers are International Safety Management standards (ISM) compliant

- Extensive & mandatory pre-trip inspections of Reefer container and machinery before release to customers

* Based on Dynamar Reefer report 2018-19

- Cutting Edge Reefer Technology

-

In order to meet consumers’ growing demand of fresh perishable cargo around the world, ONE has heavily invested in building our reefer fleet of controlled atmosphere and cold treatment technology. Controlled atmosphere technology - aimed at extending the shelf life of perishable produce, ONE’s COOLXTEND CA+ technology provides unparalleled cargo care during transit.

- Precise humidity control (between 65-95% humidity range)

- Atmospheric control (wide range of controlled and modified atmosphere technology CA/MA)

- Cold treatment (CT) and bulb mode shipments (flower bulb)

- Environmental Friendly

-

ONE recognizes the business value of positive environmental practices to globally changing regulatory landscape and importance of providing low cargo foot print ocean transport service.

- Best industry practices commitment

- Reduced average energy consumption of reefer units without compromising on cargo care

- CFC-free coolant used in all ONE reefers

- Experienced Reefer Teams

-

ONE has a dedicated global reefer team based in GHQ Singapore and regional reefer steering desks and specialist reefer sales teams closely collaborate with Global Reefer Business Planning team.

- Customized reefer solutions

- Round the clock technical assistance to on board reefer shipments

- Precise Temperature Control

-

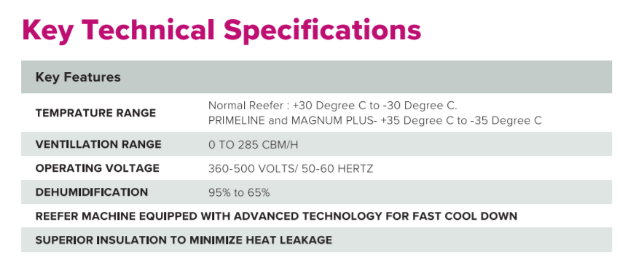

As an experienced Reefer carrier, we understand the importance of Precise and consistent temperature control is crucial specially for delicate cargo like Ice cream or Banana - where even the slightest deviation could hamper the cargo quality at destination. Hence ONE Reefer containers are equipped with superior technologies as listed below to maintain freshness of your precious cargo. Most importantly as average age of our reefer fleet is relatively much younger than industry standard; which naturally these containers can provide superior insulation to minimize heat leakage – which is also an unique advantage which our perishable customers can gain with ONE.

- Superior fast cool down technology

- Maintain steady temperature between –35°C (–31°F) and 30°C (86°F) with maximum variation of 0.5 ℃ for chilled products and 1℃ for frozen products

- Advance temperature control technology

- Worldwide Network and Service Coverage

-

- Strong worldwide network of regional offices and agency network

- Reliable operational efficiency and exceptional customer service

- Connecting more than 120 countries with 141 services

- Robust Internal Process

-

- ONE understands key factors ensuring reliable refrigerated shipments. From special care and attention to high value, time sensitive reefers such as pharmaceuticals or cold treatment shipments to ensuring an unbroken cold chain for its safe transport. Hence, in ONE we have built up a robust internal process.

- Provide extra protection to your valuable cargo

- Well trained local customer service and operations teams

- Precise temperature control

- Humidity control

- Atmospheric control

- Air exchange rate

- Appropriate packing and stuffing for different commodities

Controlled Atmosphere Technology

The transport of fresh produce is a complicated process because each variety of produce has unique characteristics that are related to recommended temperature, fresh air exchange, shelf life which affects the conditions in which they are carried in a reefer container. All fresh fruits and vegetables are living products and respire. The rate of respiration for any given product will depend on its variety (cultivar), area of growth and the seasonal and climatic conditions experienced during periods of growth. The storage life of produce varies inversely with the rate of respiration, which means that produce with short storage expectancy will usually have higher rates of respiration, eg fresh broccoli, lettuce, peas and sweetcorn. Conversely, potatoes, onions and some cultivars of grapes with low respiration rates have longer storage lives.

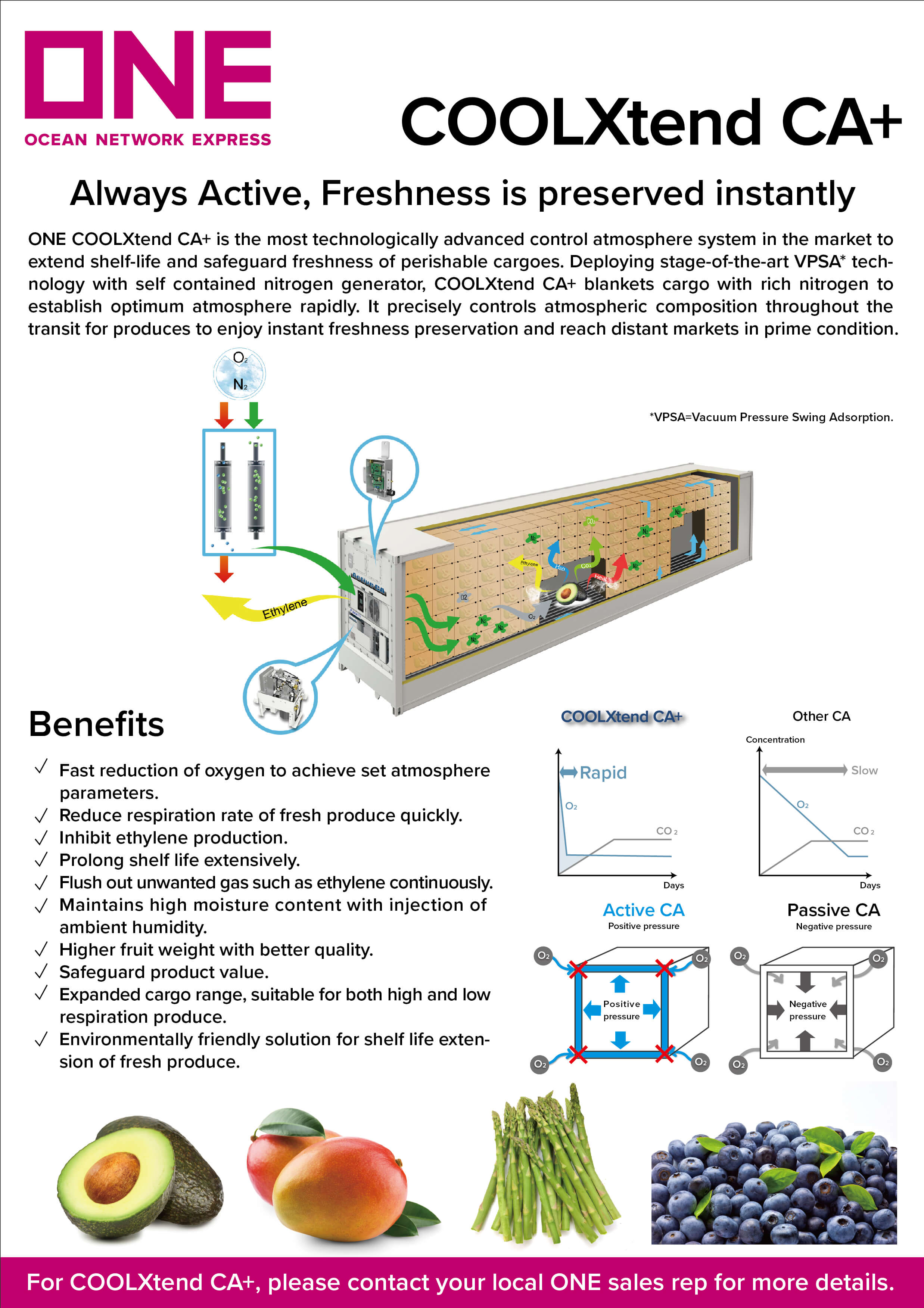

COOLXTEND CA+

Always Active, Instant Freshness

ONE COOLXTEND CA+ is the most technologically advanced control atmosphere system in the market to extend shelf-life and safeguard freshness of perishable cargoes. Deploying stage of the art VPSA* technology with self-contained nitrogen generator, COOLXTEND CA+ blankets cargo with rich nitrogen to establish optimum atmosphere rapidly. It precisely controls atmospheric composition throughout the transit for produces to enjoy instant freshness preservation and reach distant markets in prime condition. For more information, please refer to our COOLXTEND CA+ customer handout

*VPSA = Vacuum Pressure swing adsorption.

Fruits that benefit from COOLXTEND CA+: Avocado, Blueberry, Banana

COOLXTEND CA

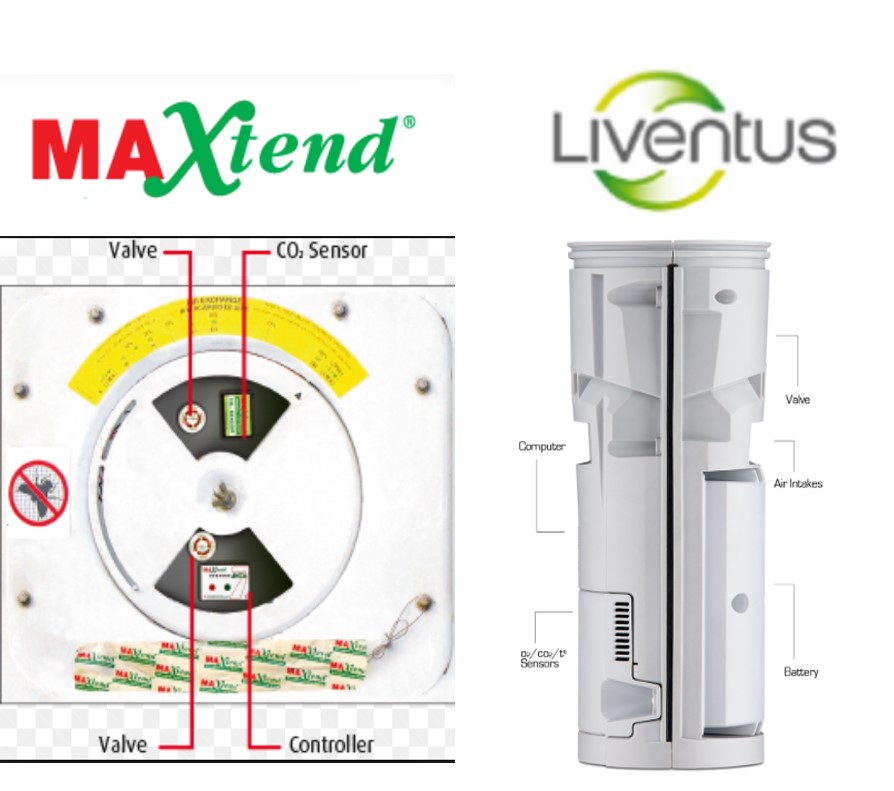

Under COOLXTEND CA solutions, ONE offers a broad range of different technologies to our customers which helps to control interior atmospheric composition of gasses to delay the ripening process of fresh fruits and vegetables. These technologies are crucial to prolong the shelf life of fruits or vegetables by adjusting the O2 and CO2 concentration of the cargo.

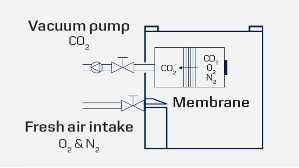

- Special Membrane technology which allows controlled removal of CO2 from atmosphere surrounding cargo to outside of the container.

- Allow ambient fresh air to regulate atmosphere inside container, when respiration lowers O2 setting.

- Vacuum pump creates pressure differential across membrane, exhausts CO2 outside of container.

- Proven its value for banana and avocado cargos, increasing the transportation window to as much as 45 days.

- Ideal for low respiring cargo; where tailor-made atmosphere is aimed via pre-trip gas injection model. An additional controller is monitoring & recording the atmospheric composition inside the reefer.

- O2 concentration by cargo respiration & fresh air injection using valves.

- CO2 Concentration by scrubbers / membrane technology & valves monitors.

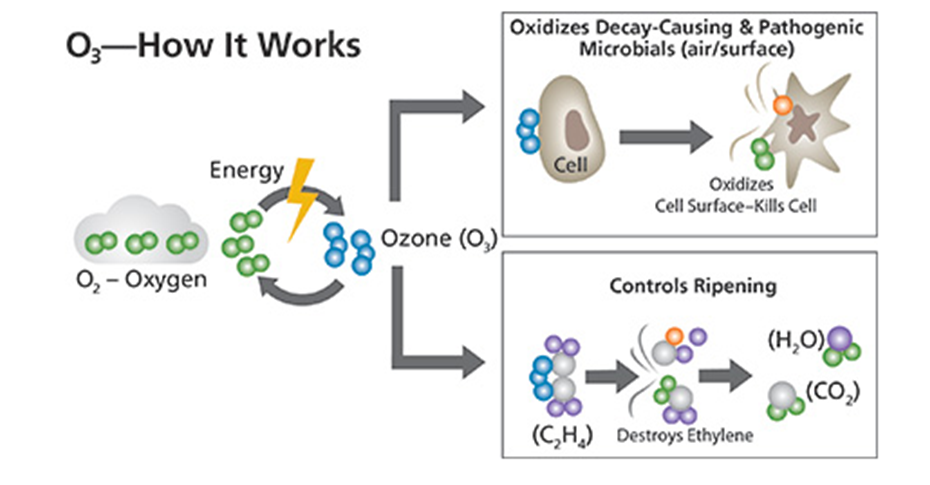

- WORLD’S ONLY door-to-door transport system that combines On-demand Ozone Generation capabilities, Real-time Monitoring and Controlled Atmosphere.

- Does not modify O2 & CO2, add ozone ( O3) to kill micro-organisms & control ethylene

- Purfresh is able to continuously generate ozone throughout the voyage, as it uses oxygen from the air.

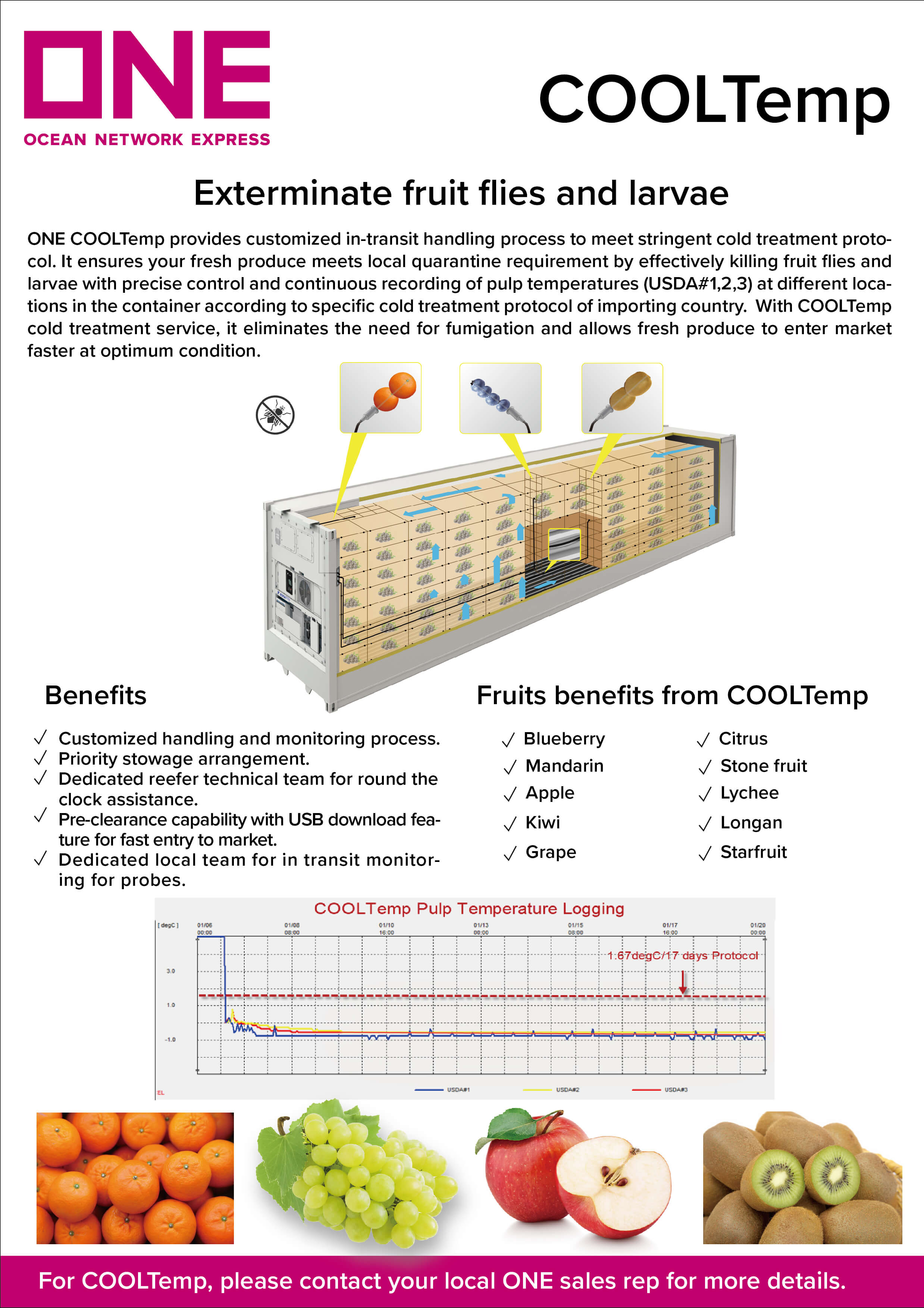

COOLTemp

Exterminate fruit flies and larvae

ONE COOLTemp technology provides customized in-transit handling process to meet stringent cold treatment protocol. It ensures your fresh produce meet local quarantine requirement by effectively kill fruit flies and larvae with precise control and continuous recording of pulp temperatures (USDA#1,2,3) at different location in the container according to specific cold treatment protocol of importing country. With CoolTemp cold treatment service, it eliminates the need for fumigation and allow fresh produce to enter market faster at optimum condition. For more information, please refer to our COOLTemp customer handout

Fruits that benefit from COOLTemp: Blueberry, Mandarin, Apple, Kiwi, Grape, Citrus, Stone fruit, Lychee, Longan, Starfruit

Fresh Air Ventilation

- Fruits and vegetables will continue to respire and produce heat and other gases (CO2 and ethylene). These gases can induce cargo damage such as discoloration and uncontrolled ripening, resulting in reduced shelf life.

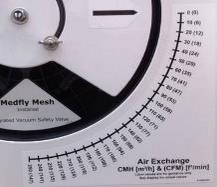

- Therefore, heat and unwanted gases should be removed from the container through ventilation (Air Exchange). Reefer containers can provide vent openings in the 0-250 m3/h range.

- The required air exchange ratio varies from commodity’s respiration rates, ethylene production and sensitivity.

- There are 2 points to remember for setting up ventilator:

1. In principle, ventilator should be closed except when transporting fresh produce (chilled mode).

2. The maximum air exchange rates vary for different reefer machine makers. Hence, it is important to specify desired air exchange rates in M3/Hour (not in percentage %) to avoid confusion.

ONE reefer containers are incorporated with different reefer machine makers to ensure fresh air ventilation for the cargo.

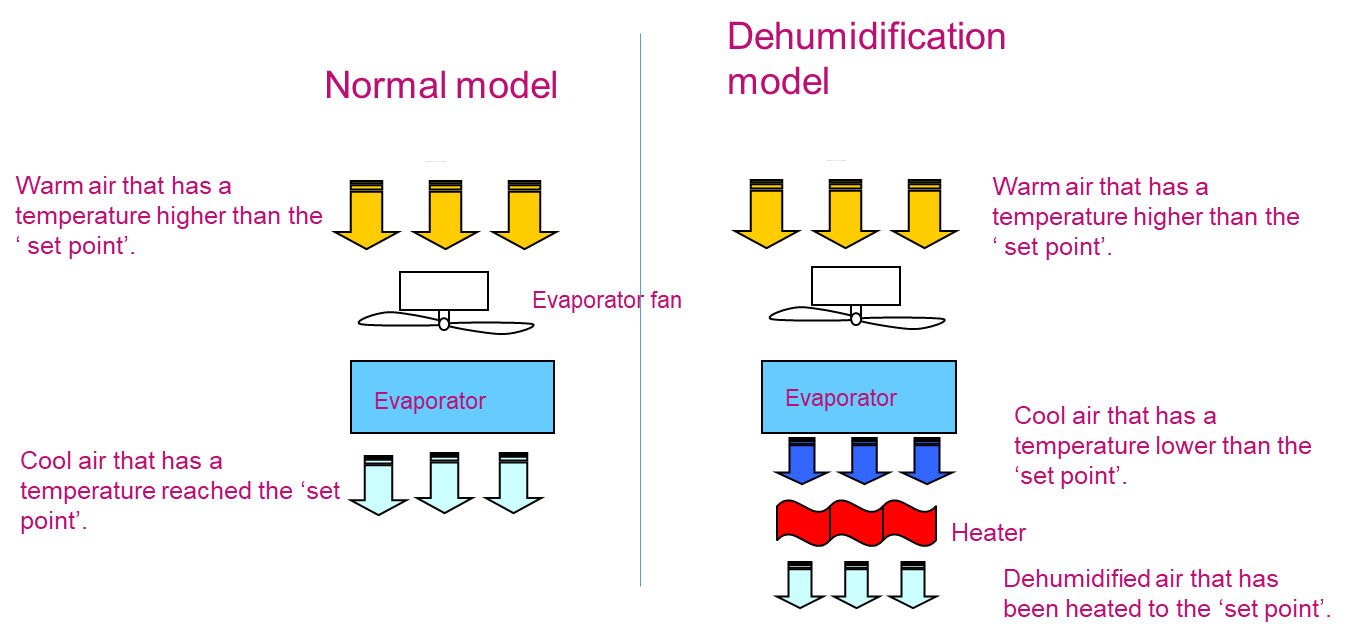

De-Humidification

ONE reefer containers are equipped with dehumidification function (selectable range between 65% to 95% RH**) in order to prevent germination and decay; which is suitable for transport of some chilled reefer cargo such as fresh garlic, onions, flower bulbs

Key points:

- Reefer machine is only equipped with De-Humidification, so as not to increase humidity inside the container.

- De-humidification is activated should humidity inside the container is higher than the humidity setting.

- The performance of dehumidification depends on type of commodity, packaging and ventilation (air exchanges) and atmosphere condition (i.e. temperature and humidity level). Hence, there is no guarantee to keep the humidity setting.

- Reefer machine is equipped with heating elements and or re-heater coil (depending on machine make) enabling dehumidification.

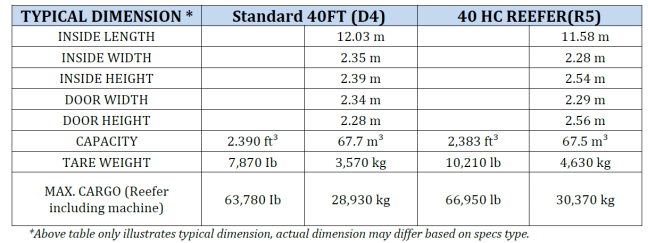

Unit Specifications

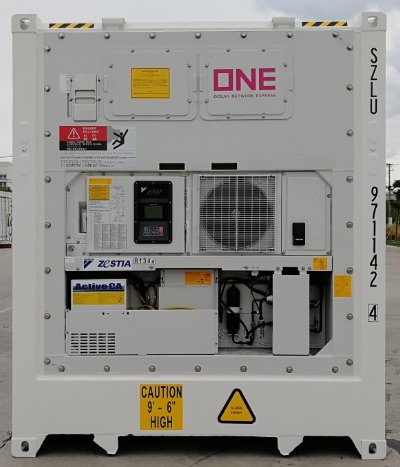

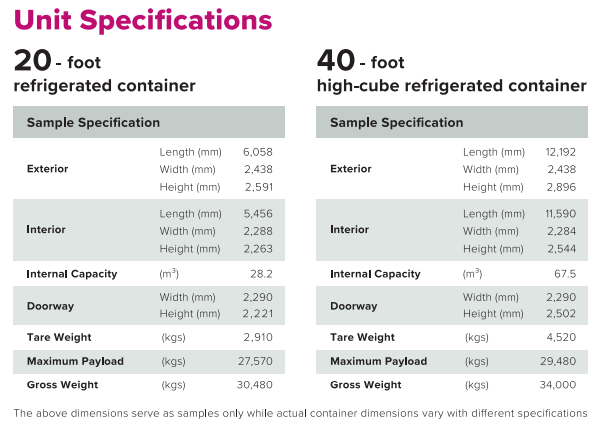

ONE has one of the largest and modern integrated reefer container fleets in the world. These containers are made of modern materials and advanced light weight refrigeration units which ensure that customers can benefit from higher payload capacity in each container. These reefer containers are mainly of two sizes i.e. 20ft and 40 HC and built according to stringent testing and highest technical standards.

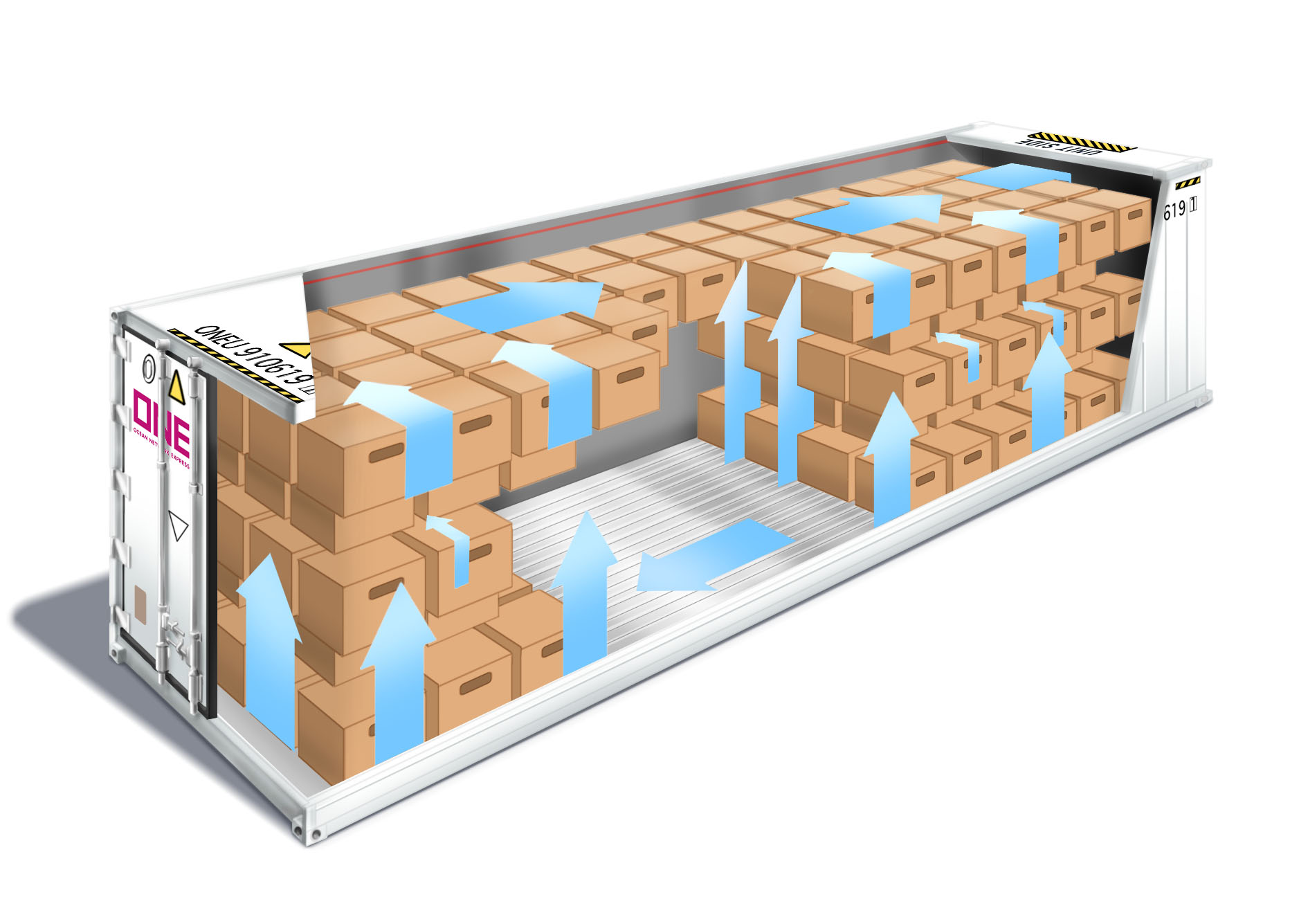

The refrigeration unit is built onto the nose of the container and power is provided by a motor generator (when container is on wheels), by terminal (when grounded in a yard) or by the ship (when laden on board). Air, cold or warm, is supplied to the inside of a container via an air duct system that enters the container from the bottom. Air circulates under, over and through the load before it returns to the refrigeration unit. This circulation is repeated continuously when the unit is in operation.

In the nose of each refrigeration units are adjustable ventilation holes. At specific settings, these vents allow fresh air exchanges to avoid a build-up of carbon dioxide inside the container. All fresh fruits and vegetables are living products and as a result, emit heat and carbon dioxide. Vents allow this warm toxic air to be expelled from the container to avoid spoilage. These advanced reefer containers are computerized, enabling highly precise temperature control. Transportation has become easier due to this type of precise control that ensures preserving the quality of foods such as meat, fish, eggs, vegetables and fruits, as well as films, plants and pharmaceuticals.

Benefits of Non-Operating Reefer (NOR) to Customers

Every year container shipping industry spends billions of dollars carrying empty reefer and dry containers to market demand locations around the world – which is logistically challenging and also inefficient in operations. NORs offer an opportunity to solve this problem thereby also contribute to reducing container shipping industry’s carbon foot prints.

Offering of Non-Operating Reefer (NOR) or Reefer as Dry (RAD), is to minimize empty reefer repositioning cost in Dry Dominant/Reefer Non-Dominant legs, especially out of Asia. ONE allows the use of reefer containers in non-operating mode to carry “approved” dry cargo to reefer demand origins. This type of cargo is known as NOR or RAD and is approved for packing into refrigerated containers for transportation without the refrigeration machinery being switched on. ONE’s NORs transport your dry cargo in a clean, food-grade insulated container with capabilities to protect against extreme shift in outside temperature.

SUPERIOR QUALITY OF CONTAINERS:

Reefer containers are generally used to carry perishable commodities only; hence quality and cleanliness of the containers surpass that of normal dry containers.

MINIMIZE TEMPERATURE FLUCTUATION:

Due to higher insulation quality of a Reefer container, NORs minimize temperature fluctuation impact to cargo during day and night. Typically commodities which are sensitive to temperature fluctuations are Chemicals/electronics devices/films/beans in bags etc.

PROTECTION AGAINST CONDENSATION AND MOISTURE:

Due to higher insulation quality of a Reefer container, NORs also provide protection to cargo against condensation and moisture.

IMMEDIATE BOOKING ACCEPTANCE, EQUIPMENT GUARANTEE, LOADING PRIORITY:

In trade lanes where ONE face typical reefer equipment imbalance, using NORs can also provide benefits to shippers such as immediate booking acceptance, equipment guarantees, loading priority over dry (although 'live' Reefer boxes will always take priority over NORs). Contact your ONE Local Sales representative for further details about ONE preferred port pairs to avail such benefits.

COMPETITIVE PRICING:

Possibility of better pricing compared to DRY at ONE Preferred port pairs. Contact your ONE Local Sales representative for further details about ONE preferred port pairs to avail such benefits.

MINIMAL DIMENSION DIFFERENCE BETWEEN 40 FT STANDARD DRY CONTAINER AND 40 HC REEFER CONTAINER

For more information, please refer to Non-Operating Reefer Brochure

CONTROLLED ATMOSPHERE

ONE’s COOLXTEND CA+ and COOLXTEND CA atmosphere management system offers a range of solutions to meet our perishable customers demand. With the help of such advance technologies it’s possible to control the internal atmospheric gas composition which in turn helps to prolong the shelf life and maintain the quality of fresh produce, enabling our customers to expand into new distant markets. We have the best solution available for your perishable produce.

At ONE we understand that reefer cargo requires a high degree of expertise and careful handling to preserve cargo freshness and extend shelf life, especially for perishable fresh fruits and vegetables segment. Providing you with best in class reefer containers, equipped with cutting edge latest technologies, is our top priority.

Atmosphere ( COOLXTEND CA+ & COOLXTEND CA Solutions)

ONE’s COOLXTEND CA+ and COOLXTEND CA atmosphere management system offers a range of solutions to meet our perishable customers demand. With the help of such advance technologies it’s possible to control the internal atmospheric gas composition which in turn helps to prolong the shelf life and maintain the quality of fresh produce, enabling our customers to expand into new distant markets. We have the best solution available for your perishable produce.

Cold Treatment (COOLTemp solution)

ONE’s COOLTemp solutions offers cold treatment (CT) or cold sterilization option to our customers - which is an important post-harvest solution aimed to disinfest fruits subject to the fruit fly or other damaging insects. ONE’s advanced reefer containers can offer manual as well as automatic CT (ACT) option to our customers from various origins to comply with destination country’s quarantine guidelines.

Fresh Air ventilation

Fresh Air ventilation is an automated system designed to remove heat and unwanted gasses released from produce respiration inside a reefer container via the fresh air vents. ONE operates one of the largest reefer container fleet equipped with Fresh air ventilation ventilation capability.

Dehumidification

ONE reefer containers are equipped with dehumidification function (selectable range between 50 to 95% RH**) in order to prevent germination and decay; which is suitable for transport of some chilled reefer cargo such as fresh garlic and onions.

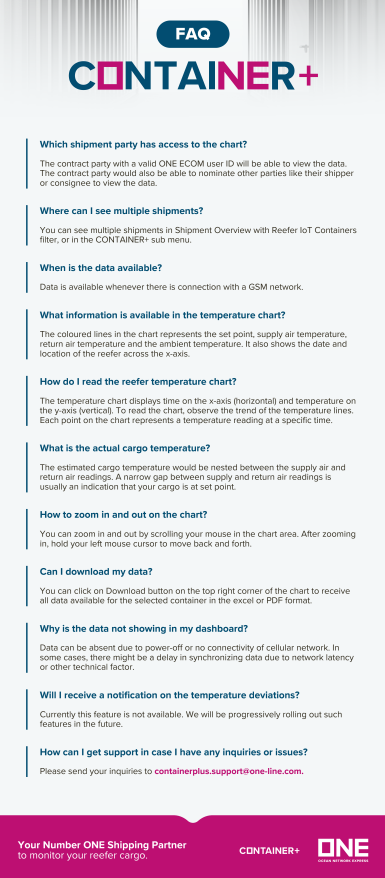

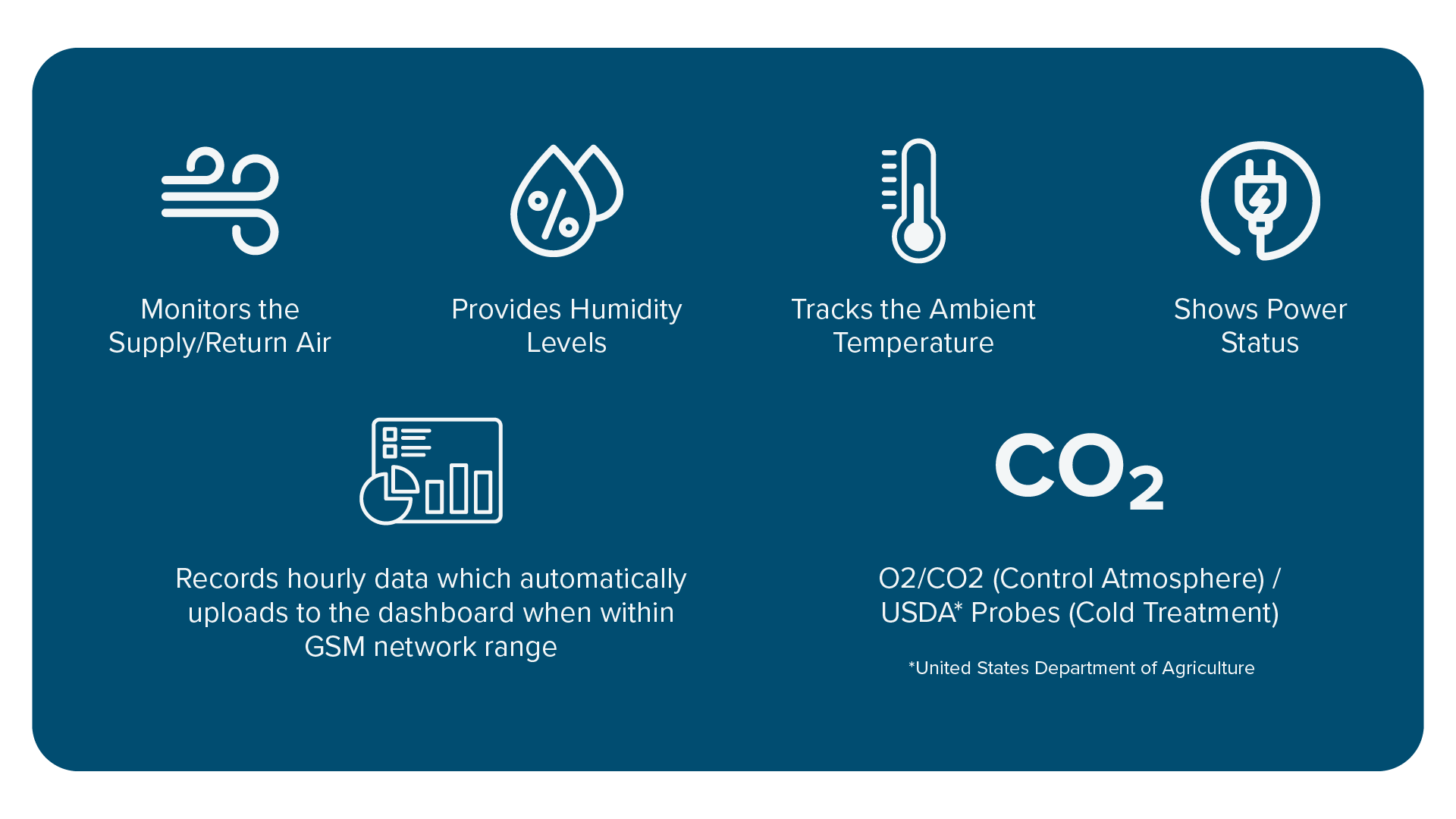

WHAT IS CONTAINER+?

ONE’s Cutting-Edge Reefer Monitoring System solution.

Transparency and full data visibility from inside your container directly to your screen, anytime and anywhere.

ONE’s advanced product, offering dashboards with near real-time monitoring and key data to empower you and your business.

WHAT DOES CONTAINER+ DO?

HOW CONTAINER+ BENEFITS YOU?

- Enhanced Visibility

• A single dashboard to view all data, reliable, detailed and user friendly. Near real time data updated hourly

• Data as charts visualisation on the ONE eCommerce platform

• Detailed cargo condition information upon request, such as cold treatment data for customs clearance

• In-transit container conditions visibility- temperature, atmosphere (O₂, CO₂), and humidity tracking

• Container movement tracking with precision

- Proactive Decision Making

• Easy access and data charts and logs downloads in Excel or PDF format

• Monitor cargo quality to minimize losses and optimize dynamic routing

• Quickly identify and address supply chain issues

- Excellence in Customer Service

• 24/7 support from ONE’s professional team of experts

We’re glad that you’re interested in CONTAINER+ for your reefer shipment monitoring. Here’s how to get started:

ONE CONTAINER + | Your Number ONE Shipping Partner to monitor your reefer cargo.

Refrigerated cargoes are usually perishable in nature, highly sensitive to temperature maintenance and likely to have a higher monetary value than most other commodities. The safe and successful carriage of refrigerated cargo critically depends on carriage instructions, which outlines the suitable and most optimum storage conditions during transportation. Although refrigerated cargo include both frozen and chilled goods, the range and diversity of the cargo can be quite extensive, including fresh fruits and vegetables; dairy products; fresh flowers; chilled/frozen fish and meat; etc. Nowadays, many pharmaceuticals are also carried in reefer containers, due to the highly sensitive and valuable in nature of the products. Chilled commodities such as fresh fruits and vegetables; begin deterioration right from the moment of being harvested as freshness gradually decreases. They can also be damaged by low temperatures, either by freezing or by chilling, causing injury to fresh produce. Hence, it makes storing and transporting them very challenging and requires specialized care, expertise and technologies to preserve freshness.

According to Food and Agriculture Organization of United Nations (FAO), about 1/3 food produced in the world for human consumption every year gets lost or wasted, leading to significant wastage of resources (including water, land, energy, labour and capital) and produce greenhouse gas emissions, contributing to global warming and climate change. As one of the leading carriers in refrigerated container industry, ONE has prepared this important guideline to raise awareness among all players involved in cold chain logistics with the goal to minimize amount of losses and food wastage. These recommendations that are considered as widely accepted best practices in the industry for handling any reefer cargo, have been drawn up to assist shippers.

Precool

While cargo pre-cooling is important; container pre-cooling could be detrimental and lead to cargo damage if not handled properly.

-

Pre-Cooling of Cargo: IMPORTANT

-

All perishable cargo should be pre-cooled to the recommended temperature before loading into a reefer container. Reefer container is designed to maintain within the range of pre-set temperature but not to achieve fast cooling of hot stuff cargo.

-

Loading without precool may cause considerable damage to cargo due to water loss and lead to spoilage for many perishable cargo.

-

If the cargo has been properly pre-cooling, temperature in the reefer container will reach the setting temperature within several hours.

-

-

Pre-Cooling of Container: AVOID

-

In case of precooled container, if the stuffing takes place in open environment then the difference in temperature outside and inside the container will cause moisture on all surfaces of the container when outside humid air flows in during the stuffing; which could be detrimental to cargo. (Picture below) This will dampen the cargo units and could cause the cargo to deform in stowage, possibly resulting in cargo damage.

-

In addition, the moisture produced on the inside of the container and the cargo will result in icing the evaporator coil once the machinery is started. Once the machinery is frosted like this, it will cause a reduction in refrigeration and hamper the airflow which will further delay unit to reach the set point.

-

One exception for Pre-Cooling the container prior to loading is when the cargo is loaded directly from a chilled storage through a tight duct between the chilled storage and the container, it called 'Cold Tunnel'. This direct linkage will prevent any moisture from entering the packing area.

-

Pre-trip Inspection

PTI – Pre-Trip Inspection is an extensive inspection done on empty reefer container to ensure that the reefer machinery is running properly at correct settings and that the container is clean and in sound condition, before allotting to customers for cargo stuffing. In ONE, our top most priority is to offer our customers with the most suitable and good quality reefer container for their needs. Hence, ONE follows a strict PTI policy by which all reefer boxes, must pass a thorough Pre-Trip Inspection (PTI) before allotting to our valued customers. Inspections conducted here are to examine the cleanliness of containers, the damages and the condition of refrigeration unit.

In addition, we also have a special PTI policy for high value, high sensitive cargo such as pharmaceuticals which has been carefully designed for preventive maintenance value based on our legacy experience in transportation of High Value commodities.

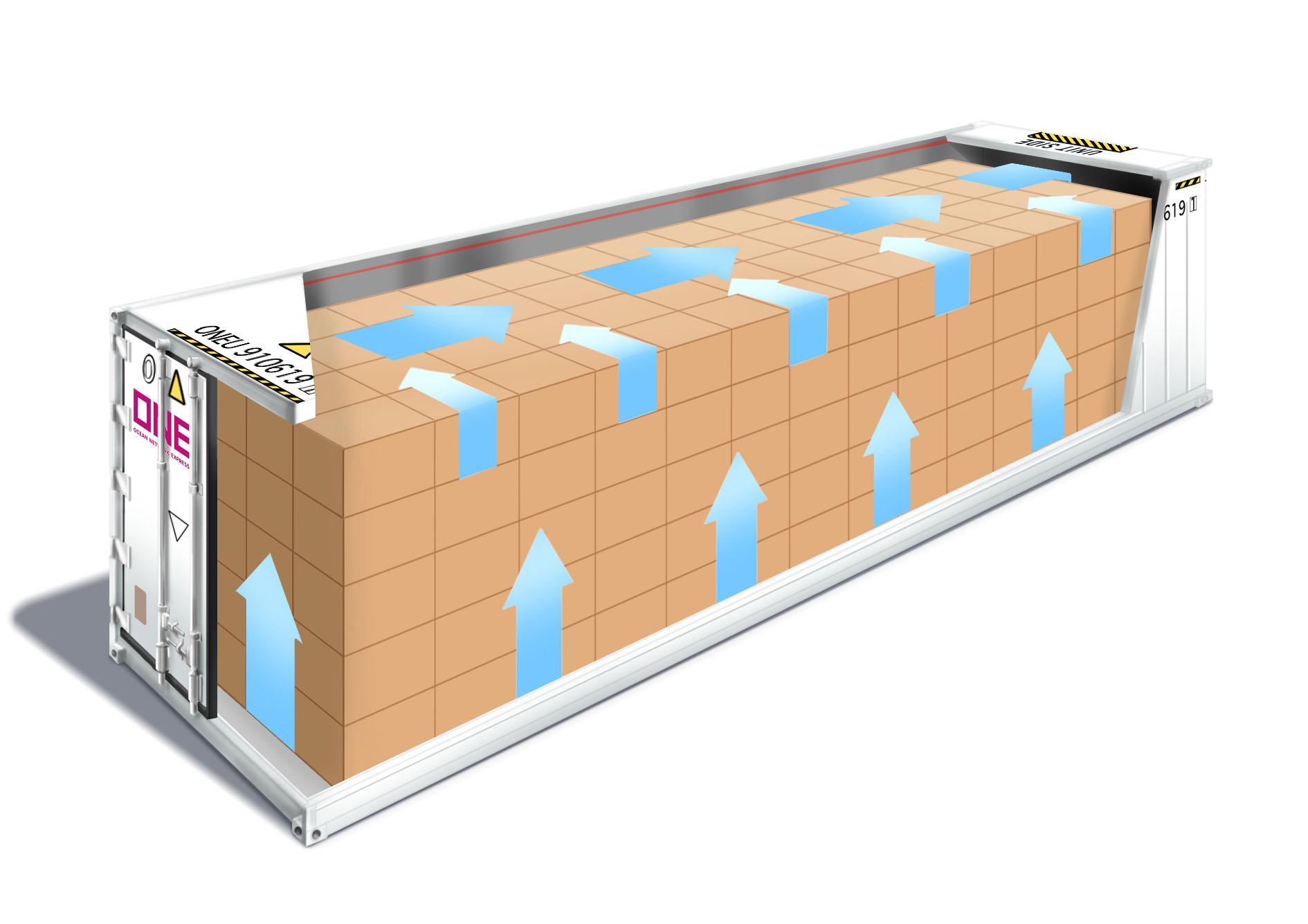

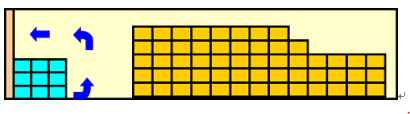

Air Circulation

In the refrigerated container, cold air circulates to wrap around the cargo. To maintain this air flow, refrigerated container has rails called T-rails laid on the floor. The cold air blown out from the freezing unit is blown into the T rail from the bottom of the unit and goes towards the door side. The cool air reaches the door, rises, passes through the top of the cargo and returns to the unit.

A red line is drawn on the wall inside the refrigerated container. It shows load restriction and indicates not to load cargo up to the height beyond the line. The red line is drawn near the ceiling and the door side. Loading more cargo over the restriction line Red line, it may lead to a poor air circulation and may not be able to maintain the cold temperature of the cargo. While stowing “Non Palletized” refrigerated cargo in flat-side wall reefer containers, slight loose stowage is suggested for smooth circulation of air evenly around the cargo and also for ensuring that any heat penetrating the container walls does not come into direct contact with the cargo package.

Chilled Cargo

Chilled cargo is highly perishable premium food which can gradually ripen during shipment. In this illustration, the degree of air flow through the cargo is largely dependent upon the stuffing pattern at the door.

Frozen Cargo

If frozen cargo is pre-cooled to the correct carrying temperature, it is only necessary for air to circulate around the periphery of the load. A block stow, i.e., one that has no deliberate spacing between any of the packages or pallets, is all that is required. However, it is necessary to ensure that air can circulate under, over and to each side and end of the stow.

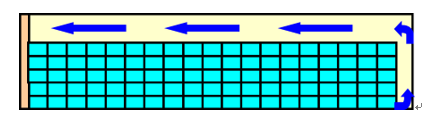

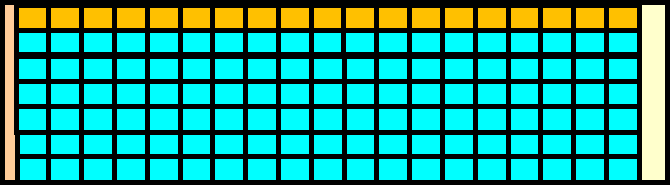

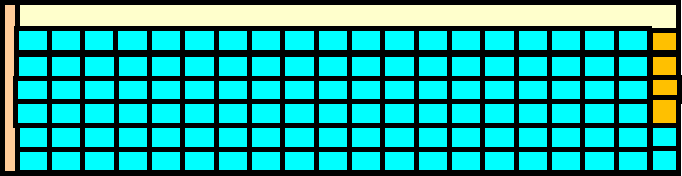

Stowage

The cold air that maintains a constant temperature is blown out from the bottom of the rear panel of the reefer unit. Then, the cold air goes through the floor rail (T-bar) to the door side. When it reaches the door, the air is sucked into the top of the rear panel and the air is circulated through the inside continuously. We called the location where the cold air is blown out as “Supply Air”, and the location where the cold air is sucked in as “Return Air”. Thus, do not block the air flow. Please see below Figure #3.

When a huge volume of cargo is loaded, the cold air circulation is entrapped, and it makes temperature control harder. There are Load Limit Mark, Red lines, to indicate the maximum loading capacity on side panels inside the container. Over loading exceeding the “Limited Lines” is prohibited. This Load Limit Mark, Red line, mounted from the ceiling to under 75mm/20ft. and 100mm/40ft. Please see below pictures.

Hence, we never recommend below examples of over loading.

Over Loading

Roof side

Door side

Roof and door side

Short Circuit

Chilled Cargo Stowage Best Practices

- The key is to allow proper air circulation and flow-through so that heat, vapour, CO₂, and other gases produced by the respiration process from chilled perishable products can be removed.

- Proper packaging such as packaging style and package material is necessary to support stacking weight and sustainability at various humidity levels.

- Any packaging accessory like shrink-wrap, slip sheets, foam trays and plastic bags which can block or obstruct air passage should not be used.

- Proper air passage on the package, including proper size/number/ places of ventholes on cartons, is needed to allow refrigerated air to circulate through all the cargo in the container.

- Proper stuffing is required to allow refrigerated air to circulate through the package material and throughout the entire load.

- If the cargo cannot cover an entire floor, cardboard can be used to cover empty spaces to allow for smooth refrigerated airflow.

- There must be no stowage above the indicated red line on the container walls to avoid impeding return air flow.

Frozen Cargo Stowage Best Practices

- As the frozen cargo should have been appropriately pre-cooled to the desired temperature before loading, air circulation should be aimed at blocking and preventing heat penetration from outside the container.

- The entire floor should be evenly loaded and covered.

- Proper corner support of cartons or pallets is needed due to the weight and loading pressure.

- Stowage must be kept below the red-line to avoid air circulation blockage. The key is to allow air circulation around the cargo.

- Ventilation and dehumidification must be set to “Off”. Drain port must be “Closed”.

- Solid block stowage, leaving no space between the packages or cartons, is preferred to avoid hot pot or short-circuiting.

Pre-loading Guideline

Before Loading Checklist

- Inspect the reefer container to ensure equipment is in good condition.

- Check and clean T-floor to ensure air channel is clear from the panel to the door.

- Pre-treat the products.

- Pre-cool the products to carriage temperature range.

Note: hot stuffing may damage both the equipment and cargo itself. - Do not pre-cool the container, except when goods are being loaded at a cold facility where these is a sealed connection to the container loading bay.

Note: While reefer cargo is generally classified according to the storage temperature, specific reefer set-points vary according to the exact cargo commodity type.

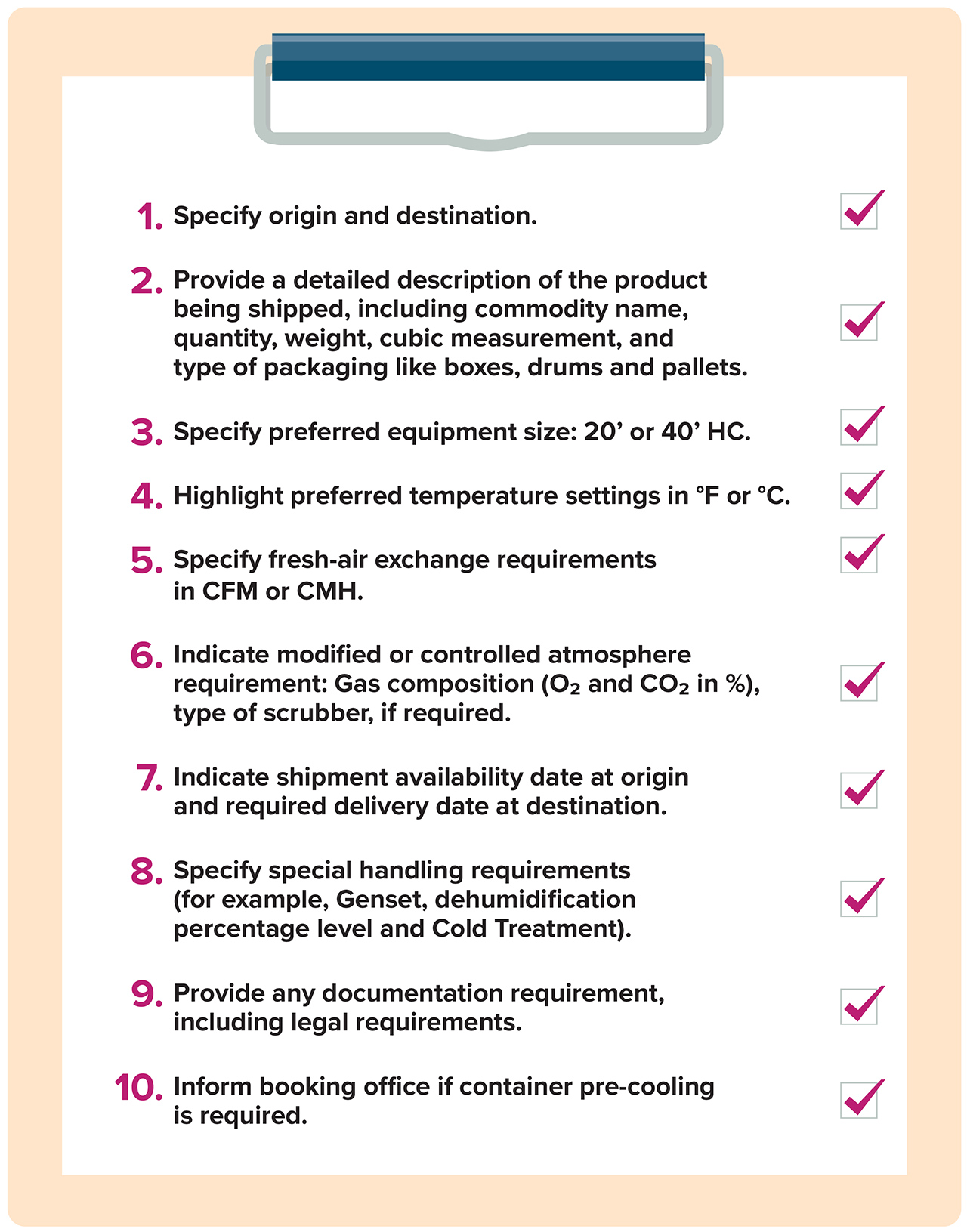

Booking Checklist

Refrigerated cargoes are usually perishable in nature, highly sensitive to temperature maintenance and likely to have a higher monetary value than most other commodities. The safe and successful carriage of refrigerated cargo critically depends on carriage instructions, which outlines the suitable and most optimum storage conditions during transportation. Although refrigerated cargo include both frozen and chilled goods, the range and diversity of the cargo can be quite extensive, including fresh fruits and vegetables; dairy products; fresh flowers; chilled/frozen fish and meat; etc. Nowadays, many pharmaceuticals are also carried in reefer containers, due to the highly sensitive and valuable in nature of the products. Chilled commodities such as fresh fruits and vegetables; begin deterioration right from the moment of being harvested as freshness gradually decreases. They can also be damaged by low temperatures, either by freezing or by chilling, causing injury to fresh produce. Hence, it makes storing and transporting them very challenging and requires specialized care, expertise and technologies to preserve freshness.

According to Food and Agriculture Organization of United Nations (FAO), about 1/3 food produced in the world for human consumption every year gets lost or wasted, leading to significant wastage of resources (including water, land, energy, labour and capital) and produce greenhouse gas emissions, contributing to global warming and climate change. As one of the leading carriers in refrigerated container industry, ONE has prepared this important guideline to raise awareness among all players involved in cold chain logistics with the goal to minimize amount of losses and food wastage. These recommendations that are considered as widely accepted best practices in the industry for handling any reefer cargo, have been drawn up to assist shippers.

Future-Proofing Perishables

"Future-Proofing Perishables" explores how Ocean Network Express (ONE) builds resilience in refrigerated cargo. This report covers global reefer trends, cold chain challenges, and ONE's solutions, including their vast fleet, Container+ technology, and expert support, ensuring reliable, protected cargo from origin to arrival.

Format PDF

Pages 16

Size 43.48MB

CONTAINER+ Flyer

CONTAINER+ Flyer

Format PDF

Pages 1

Size 1984KB

CONTAINER+ FAQ

CONTAINER+ FAQ

Format PDF

Pages 1

Size 739kB

Future-Proofing Perishables

"Future-Proofing Perishables" explores how Ocean Network Express (ONE) builds resilience in refrigerated cargo. This report covers global reefer trends, cold chain challenges, and ONE's solutions, including their vast fleet, Container+ technology, and expert support, ensuring reliable, protected cargo from origin to arrival.

Format PDF

Pages 16

Size 43.48MB

CONTAINER+ Flyer

CONTAINER+ Flyer

Format PDF

Pages 1

Size 1984KB

CONTAINER+ FAQ

CONTAINER+ FAQ

Format PDF

Pages 1

Size 739kB

CONTACT ONE FOR YOUR REEFER SHIPMENTS

We will be glad to assist with your reefer shipments.

Contact your local ONE representative for more information.